It is very common to have CFS and Structural Steel framing on the same project. This is what most people envision when they hear “steel framing”. Because it is thicker and heavier than light gauge steel, the best fastening methods employ welding, bolting, or riveting. Used in conjunction with concrete, the most durable structures employ structural steel. Structural steel projects are framed out with heavy, large members and used for framing out large open spaces and buildings, bridges, and industrial sites. “Hot-rolled” means the member is shaped while the steel is molten hot.

COLD FORMED STEEL FRAMING WALL SECTIONS SERIES

“Cold-Formed” means the sections are shaped at room temperature by guiding the steel through a series of rollers.

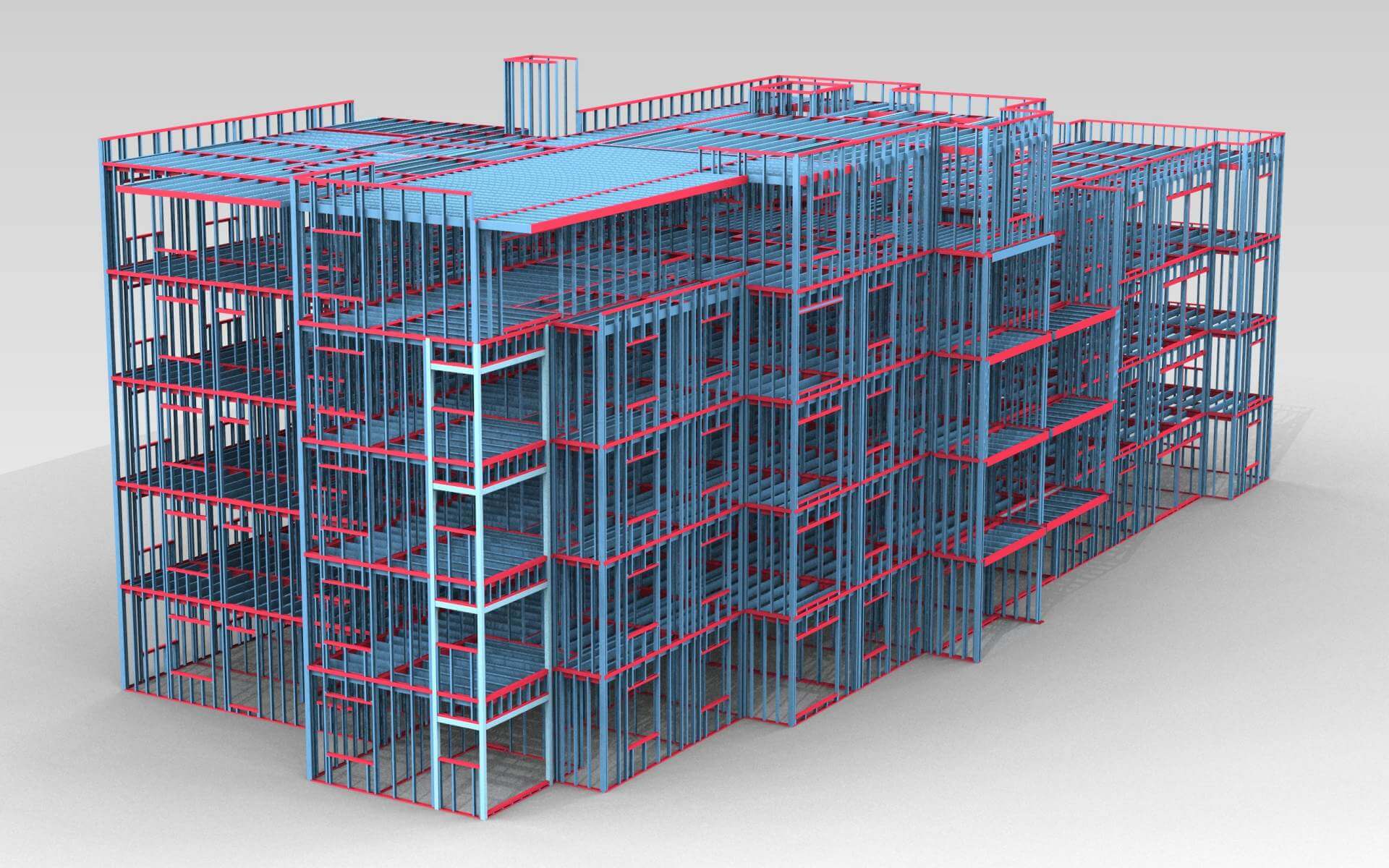

When using steel framing, there are two main options to consider: Cold-Formed Steel and Structural Steel. Steel has an outstanding strength-to-weight ratio and flexes with force, which is why it’s frequently used for large construction projects like high-rise buildings. Today we are going to take a deep dive into what we mean when we say “Cold-Formed Steel”. The term “Steel” is one of those broad terms that gets thrown around a lot. With lumber prices soaring, developers are looking for steel solutions. Metal Furring Sizesīoth hat channels (left) and zee furring (right) are used to apply gypsum wall board to a concrete or CMU block wall.We’ve recently discussed cold-formed steel and how it can be utilized with Industrialized Construction. The taller leg of the J Track goes on the shaft-side of the wall to help hold the shaft liner in place.

After the shaft liner is installed, gypsum wall board is installed as usual from the floor-side of the wall. The 1" portion of the stud holds a 1" shaft liner, which can be installed from the floor-side of the wall fasteners are not required to hold the shaft liner in place. Shaftwall is used when only one side of the wall is accessible, as in mechanical shafts where there is no floor on one side of the wall. Combined with a layer of 5/8" gypsum wall board on both sides will give a 4 7/8" thick wall. The most common size stud is a 3 5/8" wide stud. The most common shapes are diagrammed below, with dimensions. The advantages of LGMF are many, including: light weight, no warping, easy cutting, and fast installation.Ĭold formed metal framing comes in many shapes and sizes. It is also being used in some residential applications. Cold formed metal framing, also referred to as light gauge metal framing (LGMF), has overtaken wood stick framing in commercial and institutional construction.

0 kommentar(er)

0 kommentar(er)